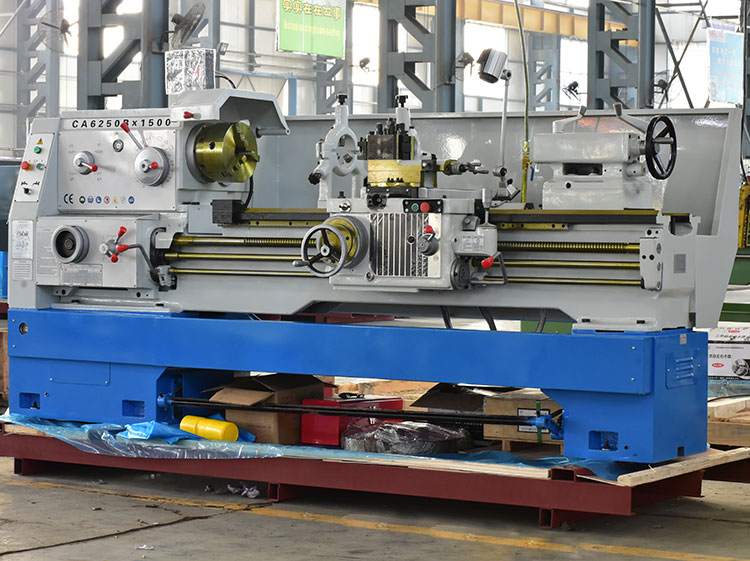

Lathes wamba ndi yopingasa lathes kuti akhoza pokonza mitundu yosiyanasiyana ya workpieces monga mitsinje, zimbale, mphete, etc. Kubowola, reaming, pogogoda ndi knurling, etc.

ntchito yomanga

Zigawo zazikulu za lathe wamba ndi: headstock, feed box, slide box, tool rest, tailstock, smooth screw, lead screw ndi bed.

Headstock: Imadziwikanso kuti mutu wamutu, ntchito yake yayikulu ndikudutsa njira yozungulira kuchokera pagalimoto yayikulu kudzera munjira zingapo zosinthira liwiro kuti shaft yayikulu ipeze ma liwiro osiyanasiyana ofunikira a kutsogolo ndi kumbuyo, komanso nthawi yomweyo headstock amalekanitsa gawo la mphamvu Pass motion ku bokosi chakudya.Headstock Medium spindle ndi gawo lofunikira la lathe.Kusalala kwa spindle yothamanga pa bere kumakhudza mwachindunji kukonzedwa kwa ntchito.Kulondola kwa kasinthasintha kwa spindle kukachepetsedwa, mtengo wogwiritsa ntchito chida cha makinawo udzachepetsedwa.

Bokosi lazakudya: Limadziwikanso kuti bokosi lazida, bokosi lazakudya lili ndi njira yosinthira liwiro yoyendetsera kudyetsa.Sinthani makina osinthira liwiro kuti mupeze kuchuluka kwa chakudya kapena phula lofunikira, ndikutumiza ku mpeni kudzera pa screw yosalala kapena wononga.choyikapo kudula.

Mtsogoleli ndi wononga zosalala: zomwe zimagwiritsidwa ntchito polumikiza bokosi lodyera ndi bokosi lotsetsereka, ndikutumiza kusuntha ndi mphamvu ya bokosi lodyera kubokosi lotsetsereka, kotero kuti sliding

moyo pamwamba

Crate imapeza kusuntha kwa mzere wautali.Chowotcha chimagwiritsidwa ntchito makamaka potembenuza ulusi wosiyanasiyana.Potembenuza malo ena a workpiece, screw yosalala yokha imagwiritsidwa ntchito, ndipo chowongolera sichigwiritsidwa ntchito.

Slide box: Ndi bokosi lowongolera la kayendedwe ka lathe.Ili ndi makina omwe amatembenuza mayendedwe ozungulira a bar yowunikira ndi zomangira zotsogola kukhala mzere wozungulira wa chida chopumira.Kuyenda kwa nthawi yayitali komanso kusuntha kwa chakudya chotsalira kwa zida zimazindikirika kudzera munjira yolumikizira kuwala.Ndi kusuntha mofulumira, mwa wononga galimoto chofukizira chida kuti kotenga nthawi liniya zoyenda, kuti kutembenuza ulusi.

Chosungira chida: Chosungira chida chimapangidwa ndi zigawo zingapo za zosungira zida.Ntchito yake ndikuchepetsa chida ndikupangitsa chidacho kuyenda motalika, mozungulira kapena mozungulira.

Tailstock: Ikani malo akumbuyo kuti muyike thandizo, ndipo mutha kukhazikitsanso zida zomangira mabowo monga zobowola ndi ma reaams pokonza dzenje.

Bedi: Mbali zazikulu za lathe zimayikidwa pabedi, kuti zikhalebe ndi malo olondola panthawi ya ntchito.

zowonjezera

1. Tchuck wa nsagwada zitatu (za cylindrical workpieces), chuck wa nsagwada zinayi (zopangira zosagwirizana)

2. Live Center (yokonza zogwirira ntchito)

3. Pakatikati chimango (chokhazikika chogwirira ntchito)

4. Ndi chogwirira mpeni

chachikulu mbali

1. Torque yayikulu pamafupipafupi otsika komanso kutulutsa kokhazikika

2. Kuwongolera vekitala wapamwamba kwambiri

3. Kuyankha kofulumira kwa torque komanso kukhazikika kothamanga kwambiri

4. Chepetsani ndikuyimitsa mwachangu

5. Mphamvu zotsutsana ndi kusokoneza

Njira zogwirira ntchito

1. Kuyendera musanayendetse galimoto

1.1 Onjezani mafuta oyenerera malinga ndi tchati chopaka mafuta pamakina.

1.2 Yang'anani zida zonse zamagetsi, chogwirira, magawo otumizira, zida zoteteza ndi malire ndizokwanira, zodalirika komanso zosinthika.

1.3 Giya iliyonse iyenera kukhala pamalo a zero, ndipo kugwedezeka kwa lamba kuyenera kukwaniritsa zofunikira.

1.4 Sizololedwa kusunga zinthu zachitsulo mwachindunji pabedi, kuti zisawononge bedi.

1.5 Chogwirira ntchito chomwe chiyenera kukonzedwa sichikhala ndi matope ndi mchenga, kuteteza matope ndi mchenga kuti zisagwere mu mphasa ndikuwononga njanji yowongolera.

1.6 Chidutswacho chisanatsekedwe, kuyesa kwagalimoto kopanda kanthu kuyenera kuchitika.Pambuyo potsimikizira kuti zonse ndi zachilendo, workpiece ikhoza kudzazidwa.

2. Njira zogwirira ntchito

2.1 Chidutswacho chikayikidwa, yambani pompa yamafuta opaka mafuta kaye kuti mphamvu yamafuta ikwaniritse zofunikira zamakina musanayambe.

2.2 Posintha choyikapo chosinthira zida, posintha gudumu lopachikidwa, magetsi ayenera kudulidwa.Pambuyo pakusintha, mabawuti onse ayenera kulumikizidwa, wrench iyenera kuchotsedwa munthawi yake, ndipo chogwirira ntchito chiyenera kulumikizidwa kuti chiyesedwe.

2.3 Mukatsitsa ndikutsitsa chogwirira ntchito, wrench ya chuck ndi magawo oyandama a workpiece ayenera kuchotsedwa nthawi yomweyo.

2.4 Chingwe cha tailstock, crank handle, etc. cha chida cha makina chidzasinthidwa kuti chikhale choyenera malinga ndi zofunikira zogwirira ntchito, ndipo chidzamangidwa kapena kutsekedwa.

2.5 Zida zogwirira ntchito, zida ndi zida ziyenera kuyikidwa bwino.Chida choyandama champhamvu chimayenera kukulitsa gawo lotsogolera muzogwirira ntchito musanayambe chida cha makina.

2.6 Mukamagwiritsa ntchito mpumulo wapakati kapena mpumulo wa chida, malowo ayenera kusinthidwa bwino, ndipo payenera kukhala mafuta odzola bwino ndikuthandizira malo okhudzana.

2.7 Pokonza zinthu zazitali, mbali yotuluka kumbuyo kwa shaft yayikulu siyenera kukhala yayitali kwambiri.

2.8 Podyetsa mpeni, mpeni uyenera kuyandikira ntchitoyo pang'onopang'ono kuti usawombane;liwiro la chonyamulira liyenera kukhala lofanana.Posintha chidacho, chida ndi chogwirira ntchito ziyenera kukhala patali yoyenera.

2.9 Chida chodulira chiyenera kumangirizidwa, ndipo kutalika kwa chida chotembenuza nthawi zambiri sikudutsa nthawi 2.5 kuposa makulidwe a chida.

2.1.0 Popanga zigawo za eccentric, payenera kukhala zotsutsana zoyenera kuti zigwirizane ndi mphamvu yokoka ya chuck, ndipo liwiro la galimoto liyenera kukhala loyenera.

2.1.1.Payenera kukhala njira zotetezera zogwirira ntchito zomwe zimadutsa fuselage.

2.1.2 Kusintha kwa makonzedwe a chida kuyenera kukhala pang'onopang'ono.Pamene nsonga ya chida ndi 40-60 mm kutali ndi gawo lokonzekera la workpiece, chakudya chamanja kapena chogwirira ntchito chiyenera kugwiritsidwa ntchito m'malo mwake, ndipo chakudya chofulumira sichiloledwa kugwiritsira ntchito chidacho.

2.1.3 Popukuta chogwirira ntchito ndi fayilo, chogwiritsira ntchito chiyenera kubwezeredwa pamalo otetezeka, ndipo wogwiritsa ntchitoyo ayang'ane ndi chuck, ndi dzanja lamanja kutsogolo ndi kumanzere kumbuyo.Pali njira yayikulu pamwamba, ndipo chogwirira ntchito chokhala ndi dzenje lalikulu sichiloledwa kukonzedwa ndi fayilo.

2.1.4 Popukuta bwalo lakunja la chogwirira ntchito ndi nsalu ya emery, wogwiritsa ntchitoyo ayenera kugwira nsonga ziwiri za nsalu ya emery ndi manja onse kuti apukutire molingana ndi kaimidwe komwe tafotokozera m'nkhani yapitayi.Ndizoletsedwa kugwiritsa ntchito zala zanu kuti mugwire nsalu yopukutira kuti mupukutire dzenje lamkati.

2.1.5 Panthawi yodyetsa mpeni, chogwiritsira ntchito mpeni chaching'ono chiyenera kusinthidwa kuti chizitsuka ndi maziko kuti maziko asakhudze chuck.

2.1.6 Pamene kudula workpieces zazikulu ndi zolemetsa kapena zipangizo, zokwanira Machining allowance ayenera kusungidwa.

3. Kuyimitsa magalimoto

3.1 Dulani mphamvu ndikuchotsa chogwirira ntchito.

3.2 Zogwirizira za gawo lililonse zimagwetsedwa mpaka zero, ndipo zida zimawerengedwa ndikutsukidwa.

3.3 Yang'anani momwe chida chilichonse chotetezera chilili.

4. Kusamala panthawi ya ntchito

4.1 Ndizoletsedwa kuti osagwira ntchito azigwiritsa ntchito makinawo.

4.2 Ndizoletsedwa kukhudza chida, gawo lozungulira la chida cha makina kapena chogwirira ntchito chozungulira.

4.3 Sizololedwa kugwiritsa ntchito kuyimitsa mwadzidzidzi.Pakachitika mwadzidzidzi, mutatha kugwiritsa ntchito batani ili kuti muyime, iyenera kufufuzidwanso molingana ndi malamulo musanayambe chida cha makina.

4.4 Sizololedwa kuponda panjanji ya kalozera, ndodo, ndodo yopukutidwa, ndi zina zotero.Kupatula malamulo, sikuloledwa kugwiritsa ntchito chogwirira ndi mapazi m'malo mwa manja.

4.5 Pazigawo zokhala ndi matuza, mabowo opukutira kapena makiyi pakhoma lamkati, scrapers ya triangular saloledwa kudula mabowo amkati.

4.6 Mpweya woponderezedwa kapena kuthamanga kwamadzi kwa pneumatic kumbuyo kwa hydraulic chuck kuyenera kufika pamtengo womwe watchulidwa musanagwiritse ntchito.

4.7 Potembenuza zogwirira ntchito zowonda, pamene kutalika kwa mbali ziwiri za mutu wa bedi kumapitirira nthawi 4 m'mimba mwake, pakati ayenera kugwiritsidwa ntchito motsatira ndondomeko ya ndondomeko.Thandizo la kupuma kwapakati kapena chidendene.Alonda ndi zizindikiro zochenjeza ziyenera kuwonjezeredwa pamene zituluka kumbuyo kwa mutu wa bedi.

4.8 Podula zitsulo zophwanyika kapena kudula kosavuta (kuphatikiza kugaya), zotchingira zoteteza ziyenera kuwonjezeredwa, ndipo ogwira ntchito ayenera kuvala magalasi oteteza.

Kagwiritsidwe Ntchito

Kugwiritsa ntchito bwino kwa lathes wamba kuyenera kukumana ndi izi: kusinthasintha kwamagetsi kwamagetsi pamalo opangira makina kumakhala kochepa, kutentha kozungulira kumakhala kotsika kuposa madigiri 30 Celsius, ndi chinyezi chachibale ndi zosakwana 80%.

1. Zofunikira zachilengedwe za malo a chida cha makina

Malo a chida cha makina ayenera kukhala kutali ndi gwero la kugwedezeka, kuwala kwa dzuwa ndi kutentha kwa dzuwa kuyenera kupewedwa, komanso kukhudzidwa kwa chinyezi ndi mpweya wotuluka kuyenera kupewedwa.Ngati pali gwero logwedezeka pafupi ndi chida cha makina, ma groove oletsa kugwedezeka ayenera kukhazikitsidwa mozungulira chida cha makina.Apo ayi, zidzakhudza mwachindunji kulondola kwa makina ndi kukhazikika kwa chida cha makina, zomwe zidzapangitse kukhudzana kosauka kwa zida zamagetsi, kulephera, ndi kukhudza kudalirika kwa chida cha makina.

2. Zofuna mphamvu

Nthawi zambiri, ma lathes wamba amayikidwa mumsonkhano wamakina, osati kutentha kozungulira komwe kumasintha kwambiri, momwe amagwiritsidwira ntchito ndi osauka, komanso pali mitundu yambiri ya zida zamagetsi, zomwe zimapangitsa kusinthasintha kwakukulu kwa gridi yamagetsi.Choncho, malo omwe ma lathes wamba amaikidwa amafunika kuwongolera mwamphamvu mphamvu yamagetsi.Kusinthasintha kwamagetsi amagetsi kuyenera kukhala komwe kuli kovomerezeka ndikukhalabe kokhazikika.Kupanda kutero, magwiridwe antchito a CNC adzakhudzidwa.

3. Kutentha

Kutentha kozungulira kwa lathes wamba ndikotsika kuposa madigiri 30 Celsius, ndipo kutentha kwachibale kumakhala kosakwana 80%.Nthawi zambiri, pali fani yotulutsa mpweya kapena chowotcha chozizira mkati mwa bokosi lamagetsi la CNC kuti musunge kutentha kwazinthu zamagetsi, makamaka chapakati pokonza gawo, nthawi zonse kapena kusiyana kwa kutentha kumasintha pang'ono.Kutentha kwakukulu ndi chinyezi kudzachepetsa moyo wa zigawo zoyendetsera dongosolo ndikuyambitsa kulephera kwakukulu.Kuwonjezeka kwa kutentha ndi chinyezi, ndi kuwonjezeka kwa fumbi kumayambitsa kugwirizana pa bolodi lophatikizana la dera ndikuyambitsa chigawo chachifupi.

4. Gwiritsani ntchito chida cha makina monga momwe tafotokozera mu bukhuli

Pogwiritsa ntchito makina opangira makina, wogwiritsa ntchito saloledwa kusintha magawo omwe amaikidwa ndi wopanga mu dongosolo lolamulira mwakufuna kwake.Kuyika kwa magawowa kumagwirizana mwachindunji ndi mawonekedwe amphamvu a gawo lililonse la chida cha makina.Ma parameter okhawo obwezera kumbuyo angasinthidwe malinga ndi momwe zilili.

Wogwiritsa ntchito sangasinthe zida zamakina momwe angafune, monga kugwiritsa ntchito hydraulic chuck kupitilira momwe amafotokozera.Wopanga amaganizira kwathunthu kufananiza kwa magawo osiyanasiyana a ulalo pokhazikitsa zowonjezera.Kusintha kwakhungu kumabweretsa kusagwirizana kwa magawo mu maulalo osiyanasiyana, komanso kumayambitsa ngozi zosayembekezereka.Kupanikizika kwa hydraulic chuck, hydraulic tool rest, hydraulic tailstock ndi hydraulic cylinder ziyenera kukhala mkati mwazovomerezeka zopanikizika, ndipo siziloledwa kuwonjezeka mopanda malire.

Nthawi yotumiza: Sep-09-2022