KUtembenuka

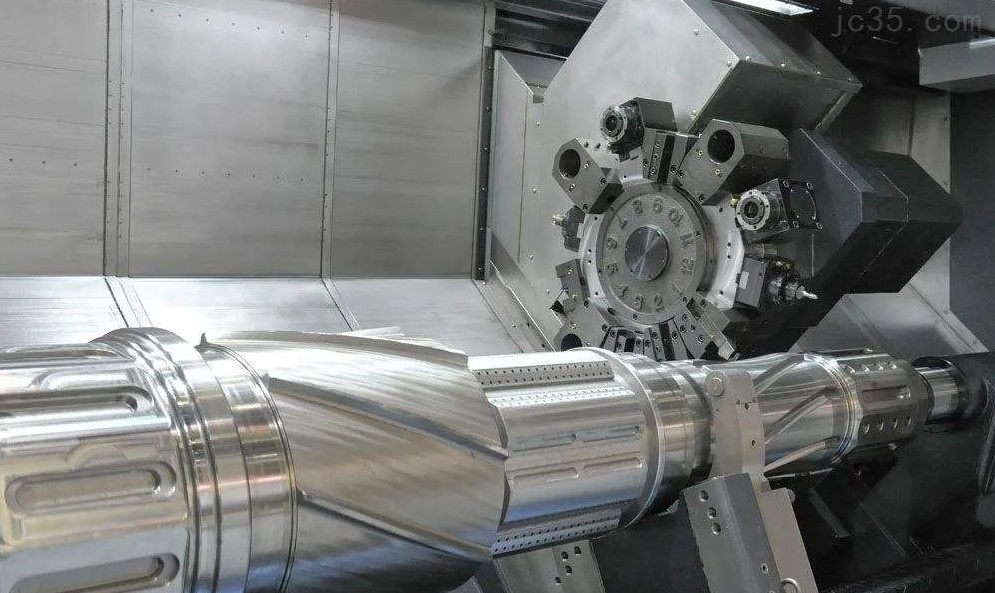

Pakutembenuka, chogwirira ntchito chimazungulira kuti chikhale chodulira chachikulu.Chidacho chikayenda motsatira njira yozungulira yozungulira, mawonekedwe amkati ndi akunja a cylindrical amapangidwa.Chidacho chimayenda motsatira mzere wa oblique womwe umadutsana ndi nkhwangwayo kuti ukhale pamwamba.Pa lathe ya mbiri kapena CNC lathe, chidachi chitha kuwongoleredwa kuti chidyetsedwe pamapindikira kuti chipange malo enaake osinthika.Pogwiritsa ntchito chida chosinthira, malo ozungulira amathanso kukonzedwa panthawi ya chakudya cham'mbali.Kutembenuza kungathenso kukonza ulusi, ndege zomalizira ndi ma eccentric shafts.Kutembenuka kolondola nthawi zambiri kumakhala IT8-IT7, ndipo kuuma kwapamtunda ndi 6.3-1.6μm.Mukamaliza, imatha kufika IT6-IT5, ndipo roughness imatha kufika 0.4-0.1μm.Kutembenuza kumakhala ndi zokolola zapamwamba, njira yodula bwino komanso zida zosavuta.

MILI

Kuyenda kwakukulu kodula ndiko kuzungulira kwa chida.Pa mphero yopingasa, mapangidwe a ndege amapangidwa ndi m'mphepete mwa kunja kwa mphero wodula.Pomaliza mphero, ndege amapangidwa ndi mapeto a nkhope m'mphepete mwa chodula mphero.Kuchulukitsa liwiro lozungulira la chodulira mphero kumatha kukwanitsa kuthamanga kwambiri ndikupangitsa kuti pakhale zokolola zambiri.Komabe, chifukwa cha kudula ndi kudula kwa mano odula mphero, zotsatira zake zimapangidwira, ndipo kudula kumakhala kosavuta kugwedezeka, motero kumachepetsa kuwongolera kwapamwamba.Izi zimakulitsanso kuwonongeka kwa chida, chomwe nthawi zambiri chimayambitsa kudulidwa kwa carbide.Nthawi zambiri pamene workpiece imadulidwa, kuzizira kwina kungapezeke, kotero kuti kutentha kwa mpweya kumakhala bwino.Malinga ndi zomwezo kapena zotsutsana ndi liwiro lalikulu la kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe kake.

1. Kukwera mphero

The yopingasa chigawo mphamvu ya mphamvu mphero ndi chimodzimodzi chakudya malangizo workpiece.Nthawi zambiri, pali kusiyana pakati pa wononga chakudya cha tebulo la workpiece ndi mtedza wokhazikika.Chifukwa chake, mphamvu yodulira imatha kupangitsa kuti chogwirira ntchito ndi tebulo zipite patsogolo limodzi, zomwe zimapangitsa kuti chakudya chikhale chadzidzidzi.kuwonjezeka, kuchititsa mpeni.Pamene mphero workpieces ndi zinthu zolimba monga castings kapena forgings, mano pansi mphero wodula choyamba kukhudza khungu lolimba la workpiece, amene amawonjezera kuvala kwa chodula mphero.

2. M'mwamba mphero

Ikhoza kupewa kusuntha komwe kumachitika panthawi ya mphero.Pa mphero, makulidwe a odulidwawo amawonjezeka pang'onopang'ono kuchokera ku ziro, kotero kuti m'mphepete mwake mumayamba kukhala ndi nthawi yofinya ndikutsetsereka pamakina odulidwa, ndikufulumizitsa kuvala kwa zida.Panthawi imodzimodziyo, panthawi ya mphero, mphamvu ya mphero imakweza chogwiritsira ntchito, chomwe chimakhala chosavuta kuyambitsa kugwedezeka, komwe ndiko kulephera kwa mphero.

Kulondola kwa makina a mphero nthawi zambiri kumatha kufika IT8-IT7, ndipo kuuma kwapansi ndi 6.3-1.6μm.

Mphero wamba nthawi zambiri imatha kukonza malo athyathyathya, ndipo kupanga odulira mphero amathanso kukonza malo opindika.The CNC makina mphero angagwiritse ntchito mapulogalamu kulamulira nkhwangwa zingapo kuti zilumikizidwe malinga ndi ubale wina kudzera dongosolo CNC mphero kunja zovuta yokhotakhota pamalo.Panthawi imeneyi, chodulira mphero nthawi zambiri chimagwiritsidwa ntchito.Makina opangira mphero a CNC ndi ofunikira kwambiri pakupangira zida zogwirira ntchito zokhala ndi mawonekedwe ovuta monga masamba amakina amagetsi, ma cores ndi maenje a nkhungu.

KUKONZA

Pamene planing, reciprocating liniya kayendedwe ka chida ndiye chachikulu kudula zoyenda.Choncho, liwiro la planing silingakhale lalitali kwambiri ndipo zokolola zimakhala zochepa.Kukonzekera kumakhala kokhazikika kuposa mphero, ndipo kulondola kwake kwa makina kumatha kufika IT8-IT7, kuuma kwapamtunda ndi Ra6.3-1.6μm, kukhazikika kwadongosolo kungathe kufika 0.02/1000, ndipo kuuma kwapamwamba ndi 0.8-0.4μm.

KUPITA

Kupera kumapangidwa ndi gudumu lopera kapena zida zina zopukutira, ndipo kusuntha kwake kwakukulu ndikuzungulira kwa gudumu lopera.The akupera ndondomeko gudumu akupera kwenikweni ophatikizana zotsatira za zochita zitatu abrasive particles pamwamba pa workpiece: kudula, chosema ndi kutsetsereka.Pamene akupera, abrasive particles okha pang'onopang'ono osamveka kuchokera ku sharpness, zomwe zimapangitsa kuti kudula kuipire kwambiri ndipo mphamvu yodulira imawonjezeka.Pamene mphamvu yodulira imaposa mphamvu ya zomatira, njere zozungulira ndi zosaoneka bwino zimagwa, kuwonetsa mtundu watsopano wa njere zowonongeka, kupanga "kudziwotcha" kwa gudumu lopera.Koma tchipisi ndi ma abrasive particles amatha kutseka gudumu.Choncho, mutatha kugaya kwa nthawi inayake, ndikofunikira kuvala gudumu lopukuta ndi chida chosinthira diamondi.

Pogaya, chifukwa pali masamba ambiri, kukonza kumakhala kokhazikika komanso kolondola kwambiri.Makina ogaya ndi chida chomaliza, kulondola kwa kugaya kumatha kufika IT6-IT4, ndipo kuuma kwapamtunda Ra kumatha kufika 1.25-0.01μm, kapena 0.1-0.008μm.Chinthu chinanso chopera ndi chakuti chimatha kukonza zitsulo zolimba.Choncho, nthawi zambiri amagwiritsidwa ntchito ngati sitepe yomaliza yokonzekera.Pakupera, kutentha kwakukulu kumapangidwa, ndipo madzi okwanira odula amafunika kuti azizizira.Malinga ndi ntchito zosiyanasiyana, akupera akhoza kugawidwa mu cylindrical akupera, mkati dzenje akupera, lathyathyathya akupera ndi zina zotero.

KUBODZA ndi KUBODZA

Pa makina obowola, kutembenuza dzenje ndi bowo ndi njira yodziwika kwambiri yopangira dzenje.Kulondola kwa makina pakubowola ndikotsika, nthawi zambiri kumangofika ku IT10, ndipo kuuma kwapamwamba kumakhala 12.5-6.3 μm.Pambuyo pobowola, kubwezeretsanso ndi kubwezeretsanso nthawi zambiri kumagwiritsidwa ntchito pomaliza ndi kumaliza.Kubowolanso kumagwiritsidwa ntchito pobwezeretsanso, ndipo chida chobwezeretsanso chimagwiritsidwa ntchito kukonzanso.Kulondola kwa reming nthawi zambiri ndi IT9-IT6, ndipo kuuma kwapamtunda ndi Ra1.6-0.4μm.Mukabwezanso ndikukonzanso, chobowola ndi remer nthawi zambiri zimatsata nsonga ya dzenje loyambirira, zomwe sizingawongolere kulondola kwa dzenjelo.Wotopetsa amakonza malo a dzenje.Kutopetsa kumatha kuchitika pamakina otopetsa kapena lathe.Potopetsa pa makina otopetsa, chida chotopetsa chimakhala chofanana ndi chida chosinthira, kupatula kuti chogwiriracho sichimasuntha ndipo chida chotopetsa chimazungulira.Kulondola kwa makina otopetsa nthawi zambiri kumakhala IT9-IT7, ndipo kuuma kwapamtunda ndi Ra6.3-0.8mm..

Kubowola Boring Lathe

KUSINTHA KWA ZINTHU KWAMBIRI

Njira zopangira mano za zida zitha kugawidwa m'magulu awiri: kupanga njira ndi njira yopangira.Chida cha makina chomwe chimagwiritsidwa ntchito pokonza dzino pamadzi ndi njira yopangira nthawi zambiri chimakhala makina opangira mphero, ndipo chidacho ndi chodula chopangira mphero, chomwe chimafuna mayendedwe awiri osavuta: kusuntha kwa chida ndi kayendedwe ka mzere.Zida zamakina zomwe zimagwiritsidwa ntchito kwambiri pokonza malo a mano popangira njira zimaphatikizira makina opangira zida ndi makina opangira zida.

KUCHITA KWAMBIRI KWA PANSI

The Machining a mbali zitatu zokhotakhota makamaka utenga njira kukopera mphero ndi CNC mphero kapena njira processing wapadera (onani Gawo 8).Copy milling iyenera kukhala ndi prototype ngati mbuye.Pa processing, profiling mutu wa mpira mutu nthawi zonse kukhudzana ndi prototype pamwamba ndi mavuto ena.Kusuntha kwa mutu wa mbiri kumasandulika kukhala inductance, ndipo kukulitsa kuwongolera kumawongolera kusuntha kwa nkhwangwa zitatu zamakina opangira mphero, ndikupanga njira ya mutu wodula womwe ukuyenda pamtunda wokhotakhota.Odula mphero nthawi zambiri amagwiritsa ntchito odulira mphero okhala ndi utali wofanana ndi mutu wa mbiri.Kuwonekera kwaukadaulo wowongolera manambala kumapereka njira yabwino kwambiri yopangira makina apamwamba.Pamene Machining pa CNC mphero makina kapena pakati Machining, ndi kukonzedwa ndi mpira-mapeto mphero wodula malinga coordinate mtengo mfundo ndi mfundo.Ubwino wogwiritsa ntchito malo opangira makina pokonza malo ovuta ndikuti pali magazini yachida pa malo opangira makina, okhala ndi zida zambiri.Pakukhwimitsa ndi kutsiriza kwa malo okhotakhota, zida zosiyanasiyana zitha kugwiritsidwa ntchito popanga ma curvature radii a malo opindika, ndipo zida zoyenera zitha kusankhidwanso.Panthawi imodzimodziyo, malo osiyanasiyana othandizira monga mabowo, ulusi, grooves, ndi zina zotero.Izi zimatsimikizira kulondola kwapang'onopang'ono kwa malo aliwonse.

KUCHITA KWAPADERA

Special processing njira amatanthauza mawu ambiri kwa mndandanda wa njira processing kuti ndi osiyana njira kudula ndi ntchito mankhwala, thupi (magetsi, phokoso, kuwala, kutentha, maginito) kapena electrochemical njira pokonza workpiece zipangizo.Njira zopangira izi zikuphatikizapo: makina opangira mankhwala (CHM), electrochemical machining (ECM), electrochemical machining (ECMM), magetsi otulutsa magetsi (EDM), makina opangira magetsi (RHM), ma ultrasonic machining (USM), laser mtengo machining (LBM), Ion Beam Machining (IBM), Electron Beam Machining (EBM), Plasma Machining (PAM), Electro-Hydraulic Machining (EHM), Abrasive Flow Machining (AFM), Abrasive Jet Machining (AJM), Liquid Jet Machining (HDM) zosiyanasiyana kompositi processing.

1. EDM

EDM ndiyo kugwiritsa ntchito kutentha kwakukulu komwe kumapangidwa ndi kutulutsa pompopompo pakati pa electrode ya chida ndi ma elekitirodi a workpiece kuti awononge zinthu zam'mwamba za workpiece kuti akwaniritse machining.Zida zamakina a EDM nthawi zambiri zimakhala ndi mphamvu zamagetsi, makina odyetsera okha, zida zamakina zamakina ndi makina osefera ozungulira.Chogwiritsira ntchito chimayikidwa pa tebulo la makina.Mphamvu yamagetsi imapereka mphamvu yofunikira pakukonza, ndipo mizati yake iwiri imalumikizidwa ndi electrode ya chida ndi chogwirira ntchito.Pamene chida elekitirodi ndi workpiece kuyandikira mzake mu madzimadzi ntchito motengeka ndi limagwirira chakudya, voteji pakati maelekitirodi amaswa kusiyana kupanga spark kumaliseche ndi kumasula kwambiri kutentha.Pambuyo pa pamwamba pa workpiece imatenga kutentha, imafika kutentha kwambiri (pamwamba pa 10000 ° C), ndipo zinthu zake zam'deralo zimazikika chifukwa cha kusungunuka kapena ngakhale gasification, kupanga dzenje laling'ono.Dongosolo la kusefera kwamadzi ogwiritsira ntchito kukakamiza madzi oyeretsedwa kuti adutse pakati pa electrode ya chida ndi chogwirira ntchito pamagetsi enaake, kuti achotse zinthu zowononga galvanic munthawi yake, ndikusefa zinthu za galvanic corrosion kuchokera kumadzi ogwirira ntchito.Chifukwa cha kutulutsa kangapo, maenje ambiri amapangidwa pamwamba pa workpiece.Chipangizo cha electrode chimatsitsidwa mosalekeza pansi pa kayendetsedwe ka chakudya, ndipo mawonekedwe ake a contour "amakopedwa" ku workpiece (ngakhale kuti chida cha electrode chidzasokonekera, liwiro lake ndilotsika kwambiri kuposa la workpiece).Chida cha makina a EDM popanga zida zofananira ndi zida zapadera zama electrode

① Kukonza zinthu zolimba, zolimba, zolimba, zofewa komanso zapamwamba zosungunuka;

②Kukonza zida za semiconductor ndi zinthu zosagwiritsa ntchito;

③ Pangani mabowo amitundu yosiyanasiyana, mabowo opindika ndi mabowo ang'onoang'ono;

④ Pangani ziboliboli zingapo zokhotakhota zitatu, monga kufota, kufa koponya, ndipo pulasitiki imafa;

⑤ Amagwiritsidwa ntchito podula, kudula, kulimbikitsa pamwamba, kujambula, kusindikiza zilembo ndi zizindikiro, ndi zina zotero.

Waya EDM Machine Tool for Machining 2D Profile Zooneka Workpieces ndi Waya Electrodes

2. Electrolytic Machining

Electrolytic Machining ndi njira yopangira zida zogwirira ntchito pogwiritsa ntchito mfundo ya electrochemical ya anodic kupasuka kwazitsulo mu electrolytes.Chogwirira ntchito chimalumikizidwa ndi mtengo wabwino wamagetsi a DC, chidacho chimalumikizidwa ndi mtengo woyipa, ndipo kusiyana kochepa (0.1mm ~ 0.8mm) kumasungidwa pakati pamitengo iwiri.Electrolyte yokhala ndi kuthamanga kwina (0.5MPa~2.5MPa) imadutsa pampata pakati pa mitengo iwiriyo pa liwiro lalikulu la 15m/s~60m/s).Pamene chida cathode ndi mosalekeza kudyetsedwa workpiece, pamwamba pa workpiece moyang'anizana ndi cathode, zinthu zitsulo mosalekeza kusungunuka malinga ndi mawonekedwe a cathode mbiri, ndi electrolysis mankhwala amachotsedwa ndi mkulu-liwiro electrolyte, kotero mawonekedwe a mbiri ya chida amafanana "kukopedwa" pa workpiece.

① Mphamvu yogwira ntchito ndi yaying'ono ndipo mphamvu yogwira ntchito ndi yayikulu;

② Sinthani mawonekedwe owoneka ngati ovuta nthawi imodzi ndikuyenda kosavuta kwa chakudya;

③ Imatha kukonza zinthu zovuta kukonza;

④ Zokolola zambiri, pafupifupi 5 mpaka 10 nthawi za EDM;

⑤ Palibe mphamvu yodulira makina kapena kudula kutentha pakukonza, komwe kuli koyenera kukonza magawo opunduka mosavuta kapena owonda;

⑥The pafupifupi Machining kulolerana akhoza kufika pafupifupi ± 0.1mm;

⑦ Pali zida zambiri zothandizira, zomwe zimakhala ndi malo akuluakulu komanso okwera mtengo;

⑧Ma electrolyte samangowononga chida cha makina, komanso amawononga chilengedwe mosavuta.Makina a Electrochemical amagwiritsidwa ntchito kwambiri pokonza mabowo, zibowo, mbiri zovuta, mabowo ang'onoang'ono akuya, kuwomba, kuwotcha, ndi kujambula.

3. Laser processing

The laser processing wa workpiece anamaliza ndi laser processing makina.Makina opangira laser nthawi zambiri amakhala ndi ma lasers, zida zamagetsi, makina owoneka bwino ndi makina amakina.Ma laser (omwe amagwiritsidwa ntchito nthawi zambiri ma lasers a state state ndi ma laser a gasi) amasintha mphamvu zamagetsi kukhala mphamvu zowunikira kuti apange matabwa ofunikira a laser, omwe amayang'aniridwa ndi makina owonera kenako amawunikiridwa pa chogwirira ntchito kuti akonze.Chogwiritsiridwa ntchitocho chimayikidwa pazitsulo zitatu zogwirizanitsa bwino, zomwe zimayendetsedwa ndikuyendetsedwa ndi ndondomeko yoyendetsera nambala kuti amalize kayendetsedwe ka chakudya chofunikira pokonza.

①Palibe zida zamakina zomwe zimafunikira;

②Kuchulukitsitsa kwamphamvu kwa mtengo wa laser ndikokwera kwambiri, ndipo kumatha kukonza pafupifupi zida zilizonse zachitsulo ndi zopanda zitsulo zomwe zimakhala zovuta kukonza;

③ Laser processing ndi sanali kukhudzana processing, ndipo workpiece si olumala ndi mphamvu;

④Liwiro la kubowola ndi kudula kwa laser ndilokwera kwambiri, zinthu zomwe zikuzungulira gawo lokonzekera sizimakhudzidwa ndi kutentha kwapakati, ndipo kutentha kwa ntchitoyo kumakhala kochepa kwambiri.

⑤ Kung'ambika kwa laser kudula ndi kopapatiza, ndipo khalidwe lapamwamba ndilobwino.Laser processing wakhala chimagwiritsidwa ntchito mu diamondi waya kujambula kufa, mayendedwe wotchi yamtengo wapatali, zikopa porous za nkhonya zoziziritsa mpweya, kabowo kakang'ono kabowo ka injini jekeseni nozzles, masamba aero-injini, etc., komanso kudula zipangizo zosiyanasiyana zitsulo. ndi zinthu zopanda zitsulo..

4. Akupanga processing

Akupanga Machining ndi njira imene mapeto nkhope ya chida kunjenjemera ndi akupanga pafupipafupi (16KHz ~ 25KHz) zimakhudza inaimitsidwa abrasive mu madzimadzi ntchito, ndi abrasive particles zimakhudza ndi kupukuta pamwamba pa workpiece kuzindikira Machining wa workpiece. .The akupanga jenereta otembenuka mphamvu pafupipafupi AC magetsi mphamvu mu akupanga pafupipafupi magetsi oscillation ndi wina mphamvu linanena bungwe, ndi otembenuka akupanga pafupipafupi magetsi oscillation mu akupanga makina kugwedera mwa transducer.~0.01mm imakulitsidwa mpaka 0.01 ~ 0.15mm, ndikuyendetsa chida kuti chigwedezeke.Kumapeto kwa chida kumakhudza tinthu tating'ono ting'onoting'ono ta abrasive particles mumadzi ogwirira ntchito mu kugwedezeka, kotero kuti mosalekeza kugunda ndi kupukuta pamwamba kuti makina azithamanga kwambiri, ndikuphwanya zinthu zomwe zili m'deralo kuti zikhale particles zabwino kwambiri ndi kugunda. izo pansi.Ngakhale pali zinthu zochepa kwambiri pakuwomba kulikonse, pamakhalabe liwiro linalake lokonzekera chifukwa cha nkhonya zambiri.Chifukwa cha kuyendayenda kwamadzimadzi ogwira ntchito, tinthu tating'onoting'ono tomwe tagunda timachotsedwa nthawi.Pamene chidacho chikuyikidwa pang'onopang'ono, mawonekedwe ake "amakopedwa" pa workpiece.

Pamene processing zovuta-kudula zipangizo, akupanga kugwedera nthawi zambiri pamodzi ndi zina processing njira gulu processing, monga akupanga kutembenuka, akupanga akupera, akupanga electrolytic Machining, ndi akupanga waya kudula.Njira zophatikizira izi zimaphatikiza njira ziwiri kapena zingapo zopangira, zomwe zimatha kuthandizira mphamvu za wina ndi mnzake, ndikuwongolera kwambiri magwiridwe antchito, kulondola kwaukadaulo komanso kuwongolera kwapamwamba kwa workpiece.

KUSANKHA NJIRA YOPHUNZITSIRA

Kusankhidwa kwa njira yopangira makina kumaganizira kwambiri mawonekedwe a gawolo, kulondola kwazithunzi ndi zofunikira za malo, zofunikira zowonongeka, komanso zida zamakina zomwe zilipo, zida ndi zina, batchi yopanga, zokolola ndi kusanthula zachuma ndi luso. ndi zinthu zina.

Njira Zopangira Zopangira Zofanana

1. Njira yopangira makina akunja

- 1. Kutembenuza movutikira→kumaliza pang'ono→kumaliza:

Chogwiritsidwa ntchito kwambiri, chokhutiritsa IT≥IT7, ▽≥0.8 bwalo lakunja litha kusinthidwa

- 2. Kutembenuza movutikira → kutembenuza pang'onopang'ono → kugaya movutikira → kugaya bwino:

Amagwiritsidwa ntchito ngati zitsulo zachitsulo zomwe zimafunikira kuzimitsa IT≥IT6, ▽≥0.16.

- 3. Kutembenuka kwaukali→kutembenuza pang'onopang'ono→kumaliza kutembenuka→kutembenuza diamondi:

Kwa zitsulo zopanda chitsulo, malo akunja omwe sali oyenera kugaya.

- 4. Kutembenuza movutikira → kutsirizitsa pang’ono → kugaya movutikira → kugaya bwino → kugaya, kumaliza kwambiri, kugaya lamba, kugaya kalirole, kapena kupukuta kuti mumalizenso motsatira 2.

Cholinga chake ndi kuchepetsa roughness ndikuwongolera kulondola kwa dimensional, mawonekedwe ndi malo olondola.

2. Njira yopangira dzenje

- 1. Dulani → kukoka movutitsa → kukokera bwino:

Amagwiritsidwa ntchito pokonza dzenje lamkati, dzenje limodzi lofunikira ndi dzenje la spline popanga magawo ambiri a manja a chimbale, okhala ndi mawonekedwe okhazikika komanso magwiridwe antchito apamwamba kwambiri.

- 2. Kubowola→Onjezani→Ream→Kubowola Dzanja:

Amagwiritsidwa ntchito pokonza mabowo ang'onoang'ono ndi apakatikati, kukonza kulondola kwa malo asanabwerenso, ndikukonzanso kuti zitsimikizire kukula, kulondola kwa mawonekedwe ndi kuuma kwa pamwamba.

- 3. Kubowola kapena kutopetsa → kumaliza pang'onopang'ono → kutopetsa bwino → kuyandama kotopetsa kapena kutopetsa diamondi

ntchito:

1) Bokosi pore pore kupanga single-chidutswa kakang'ono mtanda kupanga.

2) Kukonza dzenje ndi zofunikira zolondola kwambiri.

3) Bowo lomwe lili ndi mainchesi akulu ndi loposa ф80mm, ndipo pali mabowo oponyedwa kale kapena mabowo opangidwapo.

4) Zitsulo zopanda chitsulo zimakhala ndi diamondi yotopetsa kuti zitsimikizire kukula kwake, mawonekedwe ake ndi malo olondola komanso zofunikira zakuya.

- 4. /Kubowola (kubowola movutitsa) kugaya movutikira → kumaliza pang'ono → kugaya bwino → kugaya kapena kugaya

Ntchito: Machining a mbali zolimba kapena machining dzenje ndi zofunika mkulu mwatsatanetsatane.

fotokozani:

1) Kulondola komaliza kwa dzenje kumatengera kuchuluka kwa wogwiritsa ntchito.

2) Njira zapadera zimagwiritsidwa ntchito pokonza mabowo ang'onoang'ono owonjezera.

3.plane processing njira

- 1. Kuphera mwankhawa→kumaliza pang'ono→kumaliza→mpheroyothamanga kwambiri

Zomwe zimagwiritsidwa ntchito pokonza ndege, malingana ndi zofunikira zaumisiri za kulondola ndi kuuma kwa pamwamba pa malo okonzedwa, ndondomekoyi ikhoza kukonzedwa mosinthasintha.

- 2. /kukonza movutikira → kukonza pang'ono pang'ono → kukonza bwino → kupanga mpeni waukulu, kukwapula kapena kugaya

Amagwiritsidwa ntchito kwambiri ndipo ali ndi zokolola zochepa.Nthawi zambiri amagwiritsidwa ntchito pokonza malo opapatiza komanso aatali.Kukonzekera komaliza kwa ndondomeko kumadaliranso zofunikira zaumisiri pamtunda wopangidwa ndi makina.

- 3. Kupera (kukonza) → kumaliza pang'ono (kukonza) → kugaya movutikira → kugaya bwino → kugaya, kugaya bwino, kugaya lamba, kupukuta

Malo opangidwa ndi makina amazimitsidwa, ndipo njira yomaliza imadalira zofunikira zaumisiri pamtunda wopangidwa ndi makina.

- 4. kukoka → kukokera bwino

Kupanga kwakukulu kumakhala ndi malo opindika kapena opondapo.

- 5. Kutembenuka→Kumaliza pang'onokutembenuka→kumalizakutembenuza→kutembenuza diamondi

Lathyathyathya Machining wa sanali ferrous zitsulo mbali.

Nthawi yotumiza: Aug-20-2022