Makhalidwe a CNC makina zida pokonza

1. Zolondola kwambiri

(1) Makina a zida zamakina a CNC ali ndi kukhazikika kwakukulu komanso kukhazikika kwamafuta, ndipo njira zochepetsera zolakwika zatengedwa.Ndi cholakwikacho, imathanso kulipidwa ndi chipangizo chowongolera manambala, kotero chida chowongolera manambala chimakhala ndi makina olondola kwambiri.

(2) Njira yotumizira makina a CNC imatengera wononga mpira popanda chilolezo, njanji yowongolera, makina amagetsi okhala ndi chilolezo cha zero, ndi zina zambiri, zomwe zimathandizira kwambiri kukhazikika, kulondola komanso kubwereza kwa chida cha makina.Chida chotsogola cha makina a CNC chimatengera ukadaulo wamakina amoto, kotero kuti cholakwika cha makina amakina ndi zero.

(3) Ntchito yolipira zolakwika ya dongosolo lowongolera manambala imachotsa cholakwika cha dongosolo.

(4) Chida cha makina a CNC ndi makina opangira okha, kuchotsa zolakwa za anthu, kuwongolera kusasinthasintha kwa kukula kwa magawo omwewo, ndipo khalidwe lokonzekera ndilokhazikika.Kukhazikitsa kumodzi kumatha kupitilira kukonza njira zingapo, kuchepetsa zolakwika za unsembe.

2. Itha kukonza magawo okhala ndi mawonekedwe ovuta

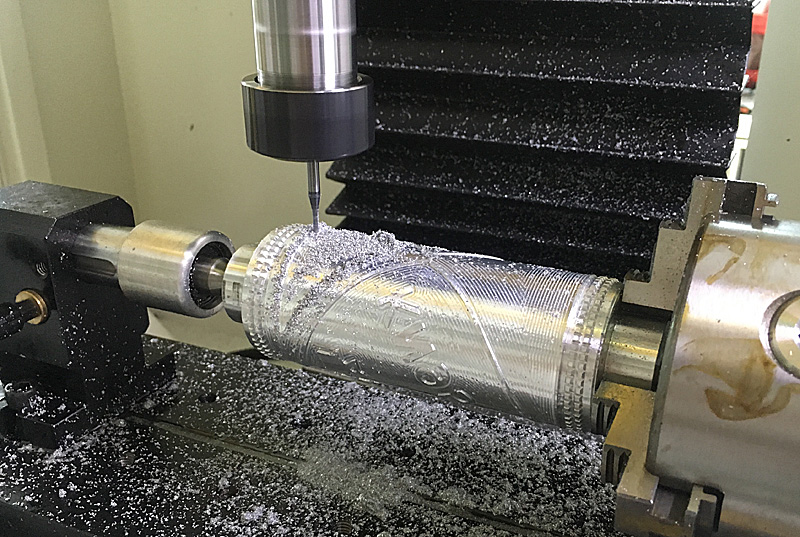

Pogwiritsa ntchito chida cha makina a CNC chokhala ndi nkhwangwa zoposa ziwiri zolumikizidwa palimodzi, imatha kukonza thupi lozungulira, kamera, ndi malo opindika osiyanasiyana omwe mabasi awo amapindika, ndipo amatha kumaliza kukonza komwe kumakhala kovuta kwa zida zamakina wamba.Mwachitsanzo, propeller yam'madzi ndi gawo lovuta lomwe lili ndi thupi lopindika, lomwe limatha kukonzedwa ndi chodulira chakumapeto ndi chida cha makina a CNC chokhala ndi ma axis asanu opingasa.

3. Kuchita bwino kwambiri

(1) Sungani nthawi yothandiza

Zida zamakina za CNC zili ndi njira zosinthira zida zodziwikiratu monga zopumira za zida za index ndi magazini a zida.Manipulator amatha kutsitsa ndikutsitsa zida ndi zida zogwirira ntchito, zomwe zimapulumutsa kwambiri nthawi yothandizira.Palibe kuyendera komwe kumafunikira popanga, kupulumutsa nthawi yoyendera.Gawo la makina likasinthidwa, kuwonjezera pa kubwezeretsanso ntchito yogwiritsira ntchito ndikusintha chida, pulogalamu yokhayo iyenera kusinthidwa, yomwe imasunga nthawi yokonzekera ndi kusintha.Poyerekeza ndi zida zamakina wamba, zokolola za zida zamakina a CNC zitha kuchulukitsidwa ndi 2 mpaka 3, ndipo zokolola zamalo opangira makina zitha kuonjezeredwa ndi khumi mpaka kangapo.

(2) Onjezani kuchuluka kwa chakudya

Zida zamakina a CNC zimatha kupulumutsa nthawi yoyendetsa bwino, kuyenda mwachangu kumafupikitsa nthawi yaulendo wopanda pake, ndipo kuchuluka kwa chakudya kumakhala kwakukulu.Angathe bwino kusankha wololera kuchuluka kwa kudula.

(3) Kudula mwachangu

Pamakina a CNC, zida zazing'ono zazing'ono, kuzama kwakung'ono, kudula pang'ono, ndikudutsa mwachangu kangapo zimagwiritsidwa ntchito kupititsa patsogolo kudula.

Mphamvu yodula ya makina othamanga kwambiri imachepetsedwa kwambiri, ndipo torque yofunikira ya spindle imachepetsedwanso.

The mapindikidwe workpiece ndi yaing'ono.Kudula kothamanga kwambiri sikumangowonjezera zokolola, komanso kumathandiza kukonza makina olondola komanso kuchepetsa kuuma kwa pamwamba.

The kusinthika ndi makhalidwe chuma CNC makina zida

1. Kusinthasintha kwamphamvu

Zida zamakina a CNC zimatha kutengera kusinthika kwamitundu yosiyanasiyana, mawonekedwe ndi kukula kwake.Mukasintha magawo kuti akhale opangidwa ndi makina, ndikofunikira kuti mutseke chogwirira ntchito ndi chilengedwe chonse, kusintha chida, ndikusintha pulogalamu yamakina, ndipo makinawo amatha kuchitidwa nthawi yomweyo.Makina owongolera manambala apakompyuta amatha kugwiritsa ntchito pulogalamu yoyang'anira dongosolo kuti awonjezere kapena kusintha magwiridwe antchito a kasamalidwe ka manambala, ndipo amatha kukwaniritsa zosowa zachitukuko chopanga.

2. Imathandizira kupanga njira zopangira zotsogola

Zida zamakina a CNC ndi zida zoyambira zopangira makina.Flexible Machining cell (FMC), flexible machining systems (FMS) ndi makompyuta ophatikizika opanga makina (CIMS) onse amatengera zida zamakina a CNC.Chida chimodzi kapena zingapo za makina a CNC, pamodzi ndi zida zina zothandizira (monga trolleys, maloboti, mabenchi osinthika, malo osungiramo zinthu zitatu, ndi zina zotero) zimapanga makina opangira makina.Dongosolo lowongolera manambala lili ndi mawonekedwe olumikizirana, omwe ndi osavuta kulumikizana pakati pa makompyuta ndikuzindikira kasamalidwe ka makompyuta ndikuwongolera njira yopangira.

3. Chuma cha zida zamakina a CNC

Mtengo wa zida zamakina a CNC ndi wokwera kuposa zida wamba zamakina, ndipo mtengo wake ndi wokwera kwambiri.Choncho, si mbali zonse ndi oyenera processing pa CNC makina zida, ndipo ali osiyanasiyana ntchito processing.Kaya ndi oyenera CNC makina chida processing ayenera kutsimikiziridwa molingana ndi mtundu kupanga, kapangidwe kukula ndi zovuta za mankhwala.

Chida chogwiritsira ntchito makina onse ndi choyenera kupanga chidutswa chimodzi komanso chaching'ono, ndipo kamangidwe kake sikovuta kwambiri.

Zida zapadera zamakina ndizoyenera kukonza zida zambiri zogwirira ntchito.

Zida zamakina a CNC ndizoyenera kukonzedwanso kwa ma batchi ovuta.

Makhalidwe a zida zamakina a CNC pakuwongolera ndikugwiritsa ntchito

Zida zamakina a CNC ndizokwera mtengo kupanga, ndipo ndi zida zazikulu zopangira zinthu zazikulu komanso njira zazikulu zamabizinesi.Makinawo akalephera, kukhudzidwa ndi kutayika kudzakhala kwakukulu.Monga zida zamakina, zida zamakina a CNC zili ndi mawonekedwe awoawo.

Mlingo waukadaulo wa kasamalidwe, magwiridwe antchito, kukonza ndi kukonza mapulogalamu ndiokwera kwambiri.Kugwiritsa ntchito zida zamakina a CNC kumadalira kwambiri pamlingo waukadaulo wa wogwiritsa ntchito, mapangidwe aukadaulo waukadaulo wa CNC komanso kulondola kwa mapulogalamu a CNC.Chifukwa chake, ukadaulo wogwiritsa ntchito zida zamakina a CNC sivuto lakugwiritsa ntchito zida wamba, koma pulojekiti yogwiritsira ntchito luso la luso, kasamalidwe, ndi kachitidwe ka zida.Ogwiritsa ntchito zida zamakina a CNC ayenera kukhala ndi chidziwitso chochuluka, ndipo panthawi imodzimodziyo ali ndi mphamvu zogwira ntchito pogwiritsira ntchito teknoloji ya CNC, kuti awonetsetse kuti zida zamakina a CNC zili ndi chiwerengero chachikulu cha kukhulupirika ndi kugwiritsira ntchito.

Mitundu ya mapulogalamu a CNC

Mapulogalamu a NC agawidwa m'magulu awiri: mapulogalamu apamanja ndi mapulogalamu odzipangira okha.

1. Mapulogalamu apamanja

(1) Kudziwa njira zamakono Malinga ndi kujambula kwa gawoli, kusanthula ndondomeko kumachitika, ndipo magawo aukadaulo monga njira yaukadaulo, kutsatizana kwa magawo ogwirira ntchito, kuchuluka kwa kudula ndi zina za gawolo zimatsimikiziridwa.Dziwani zida ndi kuchuluka kwa zida zomwe mungagwiritse ntchito.

( 2 ) Werengetsani njanji ya makina ndi kukula kwake

(3) Lembani mndandanda wa mapulogalamu ndikuwatsimikizira

(4) Lowetsani zomwe zili pamndandanda wa pulogalamu Zomwe zili pamndandanda wa pulogalamu yowongolera manambala ndikulowetsa mu chipangizo chowongolera manambala kudzera mu chipangizo cholowetsamo.

(5) Kutsimikizira ndi kuyesa kuyesa pulogalamu ya NC Yambitsani chipangizo cha NC, pangani chida cha makina a NC kuti chiwume, ndikuyang'ana kulondola kwa pulogalamuyo.Gwiritsani ntchito matabwa kapena pulasitiki m'malo mwa workpiece kuti muyese kudula kuti muwone kulondola kwa kudula.

(6) Mayesero kudula chidutswa choyamba

2. Kupanga mapulogalamu

Njira yopangira ma CNC machining mapulogalamu mothandizidwa ndi kompyuta imatchedwa automatic programming.

Kwa magawo omwe ali ndi ma geometries ovuta, kupanga mapulogalamu pamanja kumakhala kovutirapo komanso kumakhala kosavuta.

Kukonzekera ndi kuwerengetsa magawo a danga ndizovuta kwambiri, ndipo ntchito yamanja siyoyenera.M'mapulogalamu odzipangira okha, kuwerengera kwa data kumagwirizanitsa ma node, kupanga njira zopangira zida, kukonza ndi kutulutsa mapulogalamu zonse zimangochitika zokha ndi kompyuta.

Nthawi yotumiza: May-23-2022